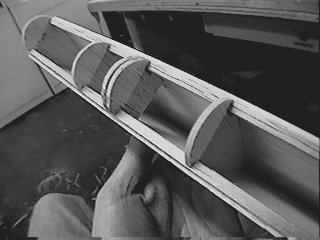

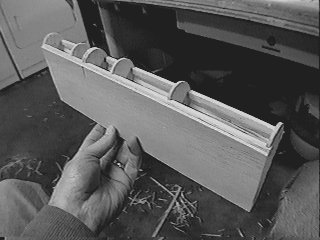

The flap is constructed in much the same way as the aileron, except the leading edge radius is larger, so you can bend a piece of 3/32" sheeting to form the leading edge. Al Master's suggestion of wrapping the wetted sheeting around a broomstick worked well, although I ended up cutting this piece a bit short before forming it.