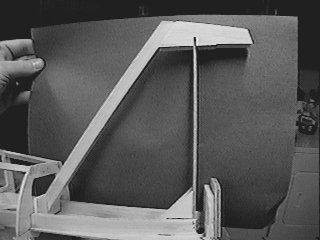

The basic framework of the lower fin. The leading edge is 3/8 x 1/2, the spar is 1/8" ply. I had to move the spar forward because of the scale hinge style I chose.

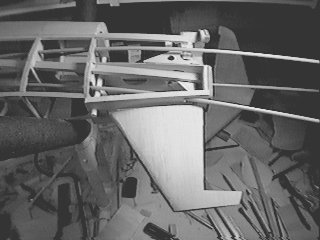

I debated whether to make the lower fin removable. I was afraid of what would happen in the event of a gear-up landing. I decided in the end that the structure would probably survive it, especially if I reinforced it just a bit, without adding too much weight. I was also afraid of a removable unit separating in flight.