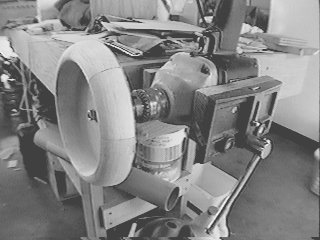

The cowl framework (as seen in the last installment) has now had 1/32 ply epoxied to the forward part. The plywood was soaked in water and wrapped around a quart paint can to establish the "curl" before gluing it on.

The circular piece of 1/16" ply in the foreground will serve as the backplate for the forward cowl ring, which will be built up from the segments stacked behind it. These were cut using a paper template on the scroll saw and sanded to shape on the bench sander.