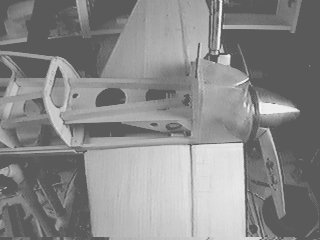

Note the paper instrument panel. This was created by scanning a photo of the real instrument panel and drawing over the image with a CAD program. The resulting drawing was then scaled to the proper size and printed. I'll use this as a pattern when I make the instrument panel from sheet plastic.